When working on construction projects, clear and accurate documentation is essential for ensuring regulatory compliance, effective asset management, and seamless future maintenance.

Fire safety is a critical aspect of building design and management. One key element in ensuring buildings and their occupants are protected is the development and maintenance of zone diagrams.

CAUTION: Need As Builts for the WA Department of Finance? Be prepared for cost increases. When it comes to submitting As Built Drawings to the Department of Finance (DOF) - Government of Western Australia, ensuring the files meet their required CADD protocol is not just a recommendation —it’s the requirement

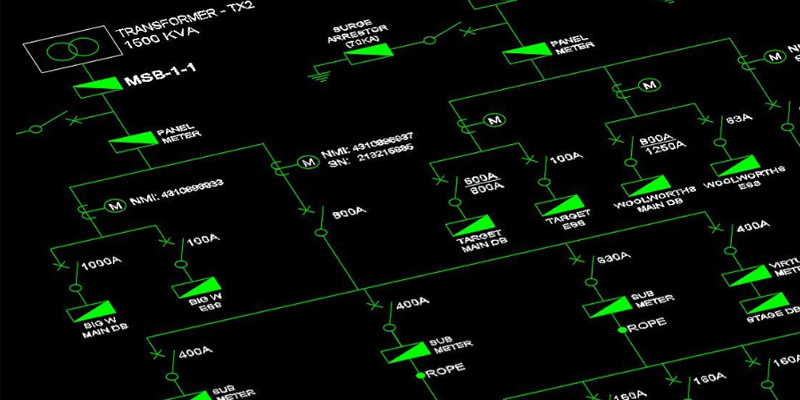

A Single Line Diagram (SLD) is a simplified representation of an electrical system, using standard symbols to represent components such as circuit breakers, transformers, busbars and cables.

Fire safety is a critical aspect of any building’s operational strategy. Whether you are responsible for a commercial building, educational facility, or residential complex, having a well-prepared and clearly communicated fire evacuation plan is essential.

In the world of the built environment development and construction development, electrical systems are vital cogs in a building that require careful documentation at project completion.

In the world of the built environment development and construction development, electrical systems are vital cogs in a building that require careful documentation at project completion.

In the world of the built environment development and construction development, electrical systems are vital cogs in a building that require careful documentation at project completion.

In the world of the built environment development and construction development, electrical systems are vital cogs in a building that require careful documentation at project completion.

In the world of the built environment development and construction development, electrical systems are vital cogs in a building that require careful documentation at project completion.